Portable buildings and modules for Point P in France | Europa Prefabri

Europa Prefabri has carried out a new modular construction project in France. On this occasion, we have designed and manufactured two portable buildings and two prefabricated modules for a Saint-Gobain Group company that are located in the Paris area.

This is a project with special characteristics, in which the design of the portable buildings has been adapted to the customer’s needs. Taking into account the use that the client will give to the constructions, the materials and the level of insulation have been adapted to the applicable thermal regulation (RT2012).

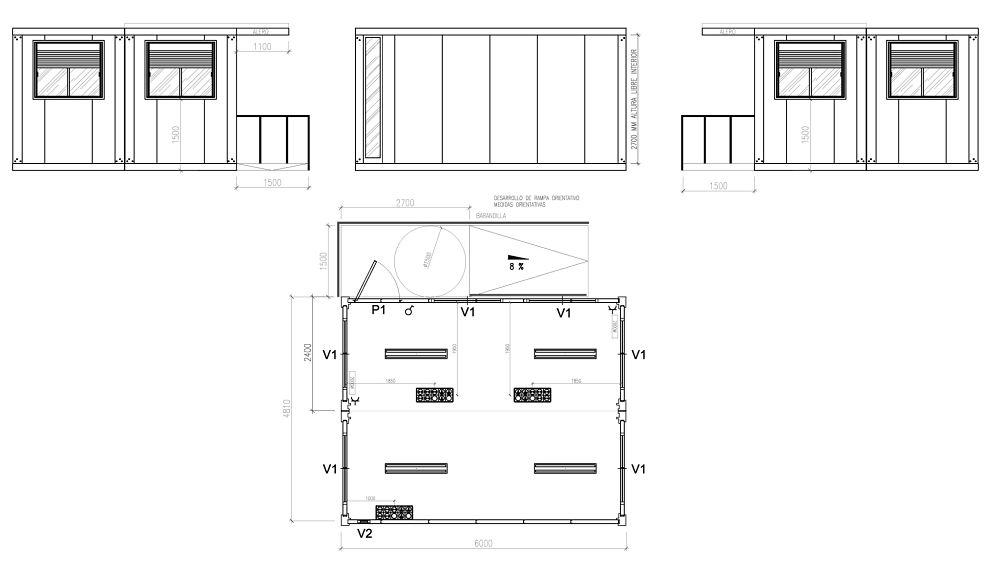

The portable buildings are composed of two prefabricated modules measuring 6.00×2.40m each. Its internal height has been increased to 2,700mm. In addition, we will also provide a ramp to access the buildings as well as an entrance canopy. In compliance with French regulations on retail spaces, the ramp and access door have been designed in accordance with the requirements for people with reduced mobility.

Technical Features: Portable buildings and modules for Point P

Floor structure

The main floor structure of the portable buildings is composed by galvanized sheet profiles of 2.00 mm thickness shaped in cold. Transversally, Omega straps are placed, providing more stability to the floor for facing vibrations and charges. The straps support an 18 mm thick phenolic plywood board covered with grey vinyl PVC floor covering Sintasol Traviata 6026 (grey).

For insulation, we have placed sandwich polyurethane panels of 100mm thickness between the straps and the plywood.

The entire floor supports loads of 250 kg/m2 using, uniformly distributed.

Roof structure

The roof structure frame in the modular building is formed by 2 vertical and 2 horizontal galvanized profiles of 2.00 mm thickness shaped in cold. OMEGA galvanized steel straps are placed transversally. These Omega steel straps support a trapezoidal galvanized metal sheet of 5 notches with the thickness of 0.6mm attached to the profiles by means of self-threading screws with washers.

Columns

The columns are formed by asymmetric galvanized steel profiles shaped in cold of 2.00mm thickness. The columns are screwed to the floor structure and roof structure using special screws. There is a round PVC pipe with the diameter of 75mm serving as a gutter hidden in the interior of the column. The column is finished on its interior with a lacquered sheet that fastens the electrical mechanisms, plugs, switches and electric protection panel.

Lateral enclosure

The side walls are formed by PUR sandwich panels 80mm thick. Each panel consists of 2 lacquered galvanized steel sheets with a thermal and acoustic insulation polyurethane layer in the middle. The polyurethane is injected with a density of 40 kg/m3.

The thermal transmission coefficient is K=0,44 Kcal/m2 h ºC. In terms of fire resistance, this kind of panel is classified as M2 material.

False ceiling

The false ceiling is formed by galvanized and pre-lacquered metallic blades in white silicone polyester (0.5mm thickness). Between the false ceiling and the roof plate, we placed a double 80+80mm insulation fiberglass blade with vapour barriers.

Carpentry

In order to guarantee compliance with thermal insulation requirements and avoid heat loss, for all the windows and glazed panels we used double glass with an air chamber 4+4/16GAS/4+4, assuring thermal break.

Electrical installation

The electrical installation system is complete except for the electrical line up to the location of the module. All the electrical system and installations are adapted to the safety requirements.

Electrical supply is connected to the electrical box with an independent protection via magneto-thermal switches and switches necessary for lighting, emergency devices (in case of having ones), air conditioning and other uses. The box is protected against the direct and indirect contacts, over current or short circuit.

Transport and assembly

We transported the prefabricated modules already assembled in order to facilitate on site installation. Due to the height of the modules, the use of special transport was necessary. Access ramps and entrance canopies were supplied disassembled.