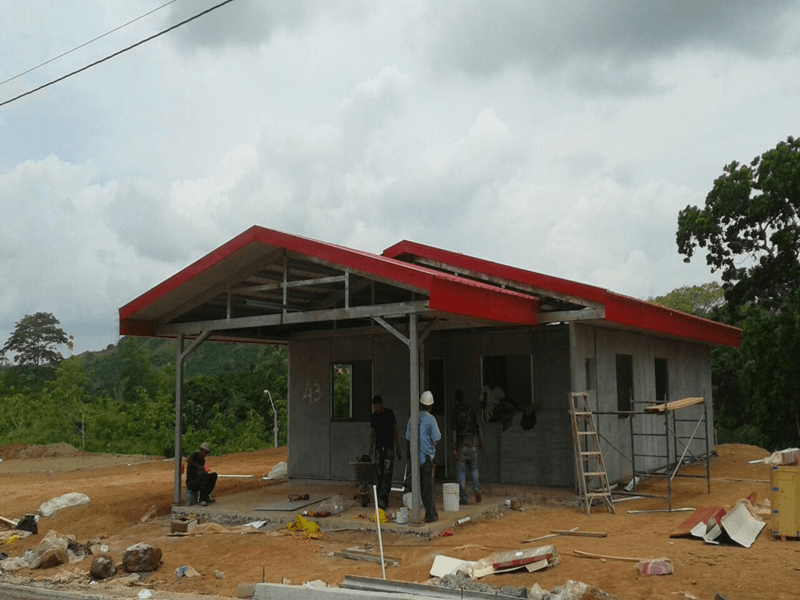

Prefabricated houses in Panama, Prefabri Steel

Prefabricated houses made with the construction system “Steel Frame Light Concrete Plus”

Prefabri Steel keeps on working on its international projection of industrialized households, in this case on a prefabricated houses new project in South America.

Industrialised construction is more environmentally friendly, efficient and with a lower cost than traditional construction. If you need to know more, visit the advantages of industrialised construction in the following link.

Our last project was assembling the first industrialised house at La Chorrera, a residential area on expansion close to Panamá City (Republic of Panamá).

We have manufactured it with the construction system Panel 1 “Steel Frame Light Concret Plus“.

This system is approved by the Technical Board of Engineering and Architecture of the Ministry of Public Works, Government of Panamá, since 2013.

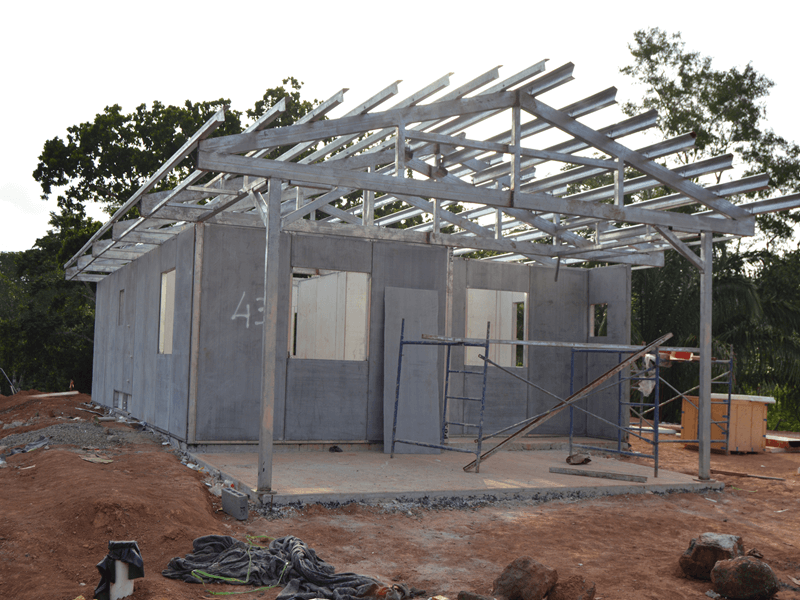

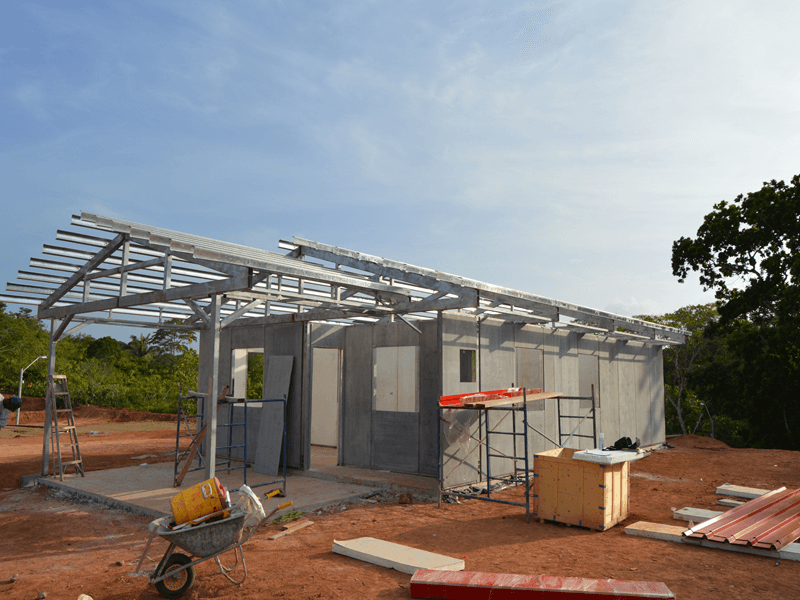

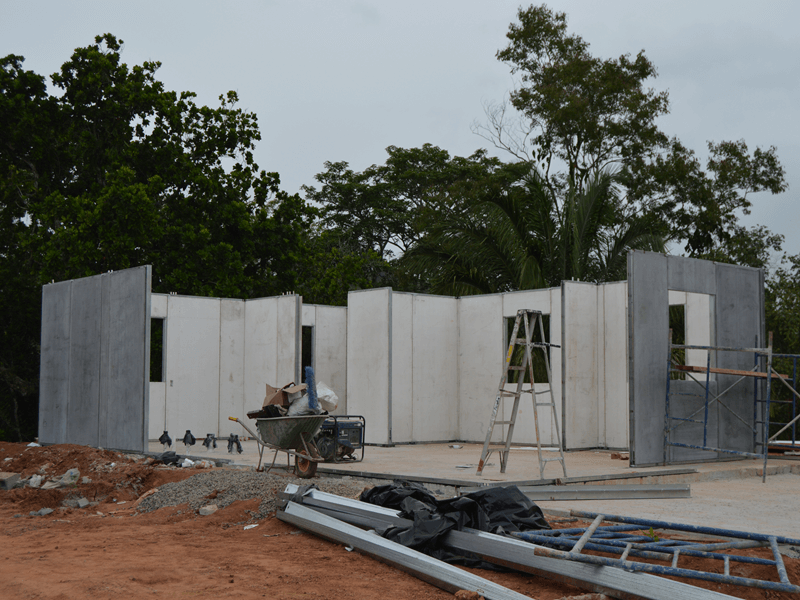

The structure assembling of the house took 2 days:

- First day: for all the industrialised panels made of lightweight concrete with polystyrene.

- Second day: assembling of trusses, straps and roof.

- The house was completely finished in 7 days.

Special offer for industrialised households

This special offer includes 225 industrialised households, which have:

- A 72 m2

- 3 bedrooms

- 2 full bathrooms.

- Kitchen, living room and dining room

- External laundry room.

- Covered parking for 2 cars

- All of it in 200 m2

This special offer includes 225 industrialised households, which have:

- A 72 m2

- 3 bedrooms

- 2 full bathrooms.

- Kitchen, living room and dining room

- External laundry room.

- Covered parking for 2 cars

- All of it in 200 m2

Assembly of modular prefabricated houses

The assembly has been made by Panamanian workers, supervised by an architect sent from Prefabri Steel to collaborate and coordinate work with our customer, who had already prepared the foundation slabs before panels and other construction elements had arrived. Local participation is a must in all our international projects.